How to properly operate rolling equipment to ensure product quality

Publication Time:

2023-07-28 14:09

Source:

How to properly operate winding equipment to ensure product quality

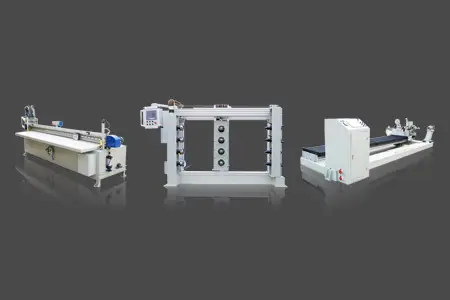

In the manufacturing and processing industries, winding equipment is a commonly used tool for winding materials into rolls. Proper operation of winding equipment is crucial for ensuring product quality. This article will guide you on how to properly operate winding equipment and highlight some key considerations.

First, it is very important to correctly set the parameters of the winding equipment. Different materials and products require different parameter settings during the winding process, including roll diameter, tension, and speed. By carefully understanding product requirements and material properties, you can adjust these parameters as needed to ensure smooth operation during the winding process and the stability of product quality.

Second, ensure correct material alignment and tension control. During the winding process, material alignment and tension are key factors. Misalignment can lead to material skew and offset, affecting the overall product quality. Uneven tension can cause material breakage or looseness, also negatively impacting product quality. Therefore, you need to pay close attention to material alignment and tension control, and adjust the equipment in a timely manner to maintain its stability.

In addition, regular inspection and maintenance of winding equipment is also very important. Winding equipment is mechanical equipment and may experience wear, loosening, or other technical problems after prolonged use. Regularly inspect the various components of the equipment, such as rollers, transmission systems, and tensioning devices, to ensure their proper operation. Repair or replace damaged parts in a timely manner to avoid product quality problems caused by equipment malfunctions.

Then, the operator's technical level and experience are also key factors in determining product quality. Only professionally trained and experienced operators can properly operate winding equipment and identify and solve potential problems during operation. Therefore, to ensure product quality, it is recommended that you provide adequate training and guidance to operators before using winding equipment, ensuring they understand the operational points and safety precautions of the equipment.

In summary, proper operation of winding equipment to ensure product quality requires attention to parameter settings, material alignment and tension control, regular inspection and maintenance of equipment, and the operator's technical level and experience. By following these key steps, you can improve product quality and achieve the desired production results.

Related News

How to choose a suitable carbon fiber equipment manufacturer

Learn how to select a suitable carbon fiber equipment manufacturer to improve production efficiency and achieve economic benefits.

Market analysis of carbon fiber equipment in the technology manufacturing industry

Carbon fiber products and equipment play a significant role in the technology manufacturing industry. This article will conduct an in-depth analysis of the market conditions of carbon fiber equipment in the technology manufacturing industry and discuss its development trends. With the widespread application of carbon fiber products, the demand for the carbon fiber equipment market is constantly growing. However, market competition is fierce, and enterprises need to enhance their competitiveness through technological innovation and brand promotion. At the same time, the continuous innovation of carbon fiber equipment technology provides more possibilities for the development of carbon fiber products.

Prospects and development trends of carbon fiber product equipment manufacturing

To learn more about the prospects and development trends of carbon fiber product equipment, please read the detailed content of this article.

Focusing on carbon fiber equipment, Weihai Yafeida leads the technological manufacturing industry

Weihai Yafeida leads the technological manufacturing industry, winning market recognition with its advanced carbon fiber equipment. As a leader in the field, they continuously innovate and develop products to meet customer needs. Weihai Yafeida boasts advanced production equipment and process technology, focusing on cooperation and communication with customers, and providing various after-sales services. In the future, they will continue to lead the development of the technological manufacturing industry and provide customers with better carbon fiber equipment.

High-quality carbon fiber equipment manufacturer, Weihai Yafeida at your service

Weihai Yafeida is a leading enterprise specializing in the manufacturing of carbon fiber equipment, providing high-quality customized solutions for customers. They possess advanced production processes and a technical team, and focus on innovation and quality control. Compared to other competitors, Weihai Yafeida has profound expertise and experience in the field of carbon fiber materials. Their professional team will provide customers with various support and services to ensure the smooth progress of projects. Contact Weihai Yafeida immediately to enjoy high-quality carbon fiber equipment manufacturing services!

Innovative technology leads the carbon fiber equipment manufacturing industry

Carbon fiber equipment plays a significant role in modern industry, and with continuous technological innovation and development, it is constantly leading new trends. This article will introduce relevant information about carbon fiber equipment and discuss its applications and prospects in innovative technologies.

Product Recommendation